Raw Materials for Cement Manufacture

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

2003). These models can be used to simulate cement grinding circuits and to assist their optimisation. The "work horse" of the cement grinding plant is the two ...

Nelson Machinery Equipment Ltd. Liquidations, Consignments, Appraisals since 1992

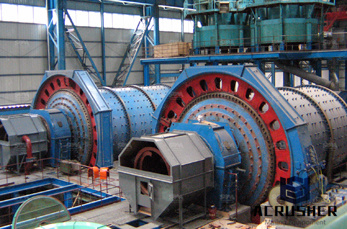

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

GRINDING ROLLS FOR VERTICAL MILLS IN THE CEMENT INDUSTRY. The operating parameters of vertical mills are seldom altered once optimum productivity is established.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

3 These differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

sale buy used machinery, second hand machinery used steam boilers used chemical machinery used generators used plastic machinery used rubber machinery and running ...

sale buy used machinery, second hand machinery used steam boilers used chemical machinery used generators used plastic machinery used rubber machinery and .

About Gulin. Looking for Information about Gulin? Visit for company news and careers as well as information about Gulin''s entire portfolio ...

MILWAUKEE M18 FUEL Deep Cut Band Saw With Redlithium XC Battery, Multivoltage charger, blade, and case Get a FREE 2nd Battery until June 30th!

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying

Millstones or mill stones are stones used in gristmills, for grinding wheat or other grains. Millstones come in pairs. The base or bedstone is stationary.

Inside a (stationary!) cement mill. The partground clinker and steel grinding media are clearly visible. (Picture courtesy Castle Cement).

SWECO VibroEnergy Grinding Mills are the most versatile line of mills available today for fast, lowcost particle size reduction to submicron range.

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Open Type Sand Mills are used in processing enamels, cement primers and emulsions. Apart from this, our sand mills are utilized for processing a wide variety of ...

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or .

Crushing plant and grinding mill are widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on.

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

K Series Mobile Crushing Plant. Based on more than 30 years'' manufacture experience, millions of equipment units'' installation experience and abundant invested in ...

Note: Click here to go directly to metallic media specifications or here for nonmetallic media specs. Grinding media, the objects used to refine material and reduce ...

Machinery and Equipment buys and sells all types of Used Processing Mills for food, pharmaceutical, chemical and mining industries. View our inventory of more than ...

WhatsApp)

WhatsApp)